SUSTAINABILITY

Innovation

Our manufacturing, printing, and raw material partners in China continually seek innovation and develop new materials, techniques, and policies to lessen our collective impact on the environment.

BMK Sustainable Partnership

We have a team of industry qualified designers, engineers, and printers ready to partner with your team. Together we can drive your environmental initiatives.

Corrugated Box Case Study

Material Usage Challenge

- The corrugated box had a great deal of excessive material that contained a product weight of 15 pounds.

- Benchmark's solution reduced material usage by 37%.

- Without compromising functionality and the environment, production cost was reduced by 20%.

Polypropylene Hanger Case Study

Material Usage Challenge

- Although Polypropylene is a recyclable polymer, it would take 20-30 years to degrade while releasing toxins into the environment. So although PP can be granulated or repurposed, it is not considered biodegradable.

- Benchmark's corrugate solution reduced environmental toxins by 100%.

- Without compromising functionality and the environment, production cost was reduced by 25%.

The requirements for printers to use FSC logos on packaging have become more strict in recent years.

Previously, merely purchasing FSC certified paper was enough. Now the printers themselves must hold a FSC certification in order to display the FSC logo.

Our printers in both China and Vietnam have passed all FSC audit requirements to become fully certified.

Utilizing FSC certified papers, and the production processes prescribed in FSC guidelines, is another way we contribute to minimizing the impact of all aspects

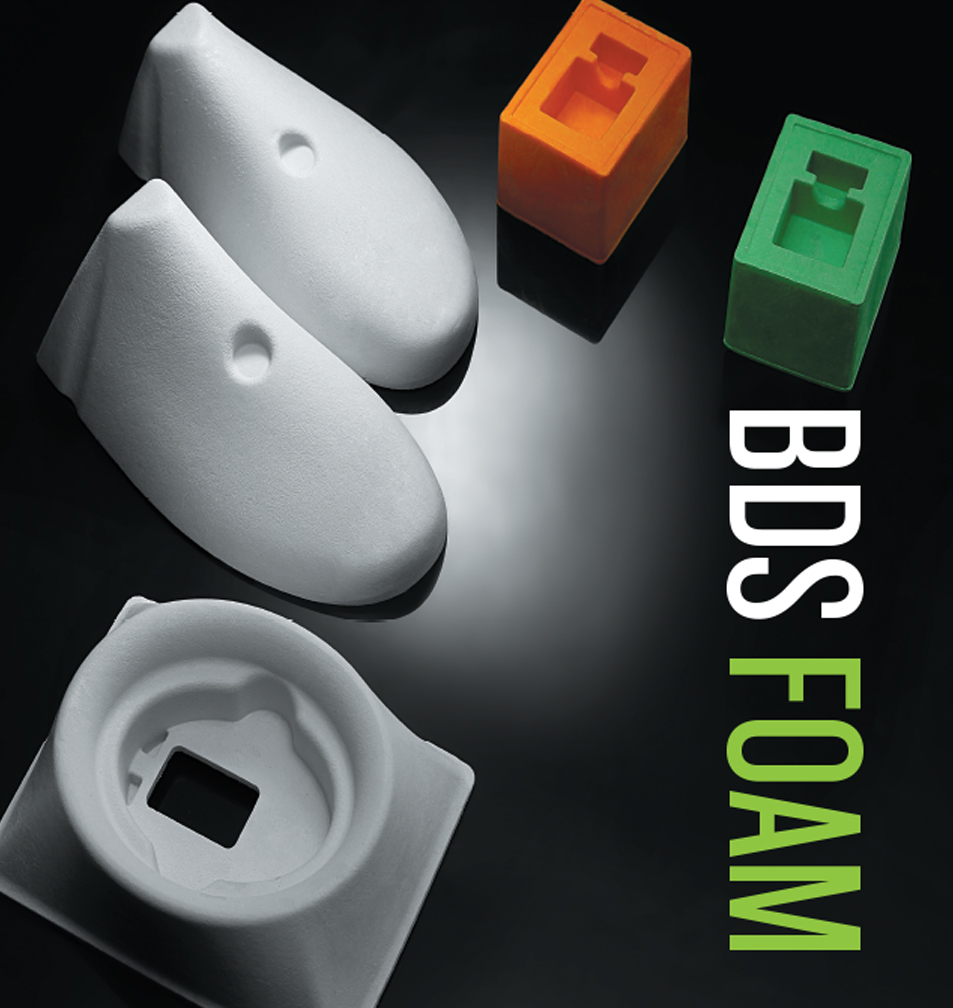

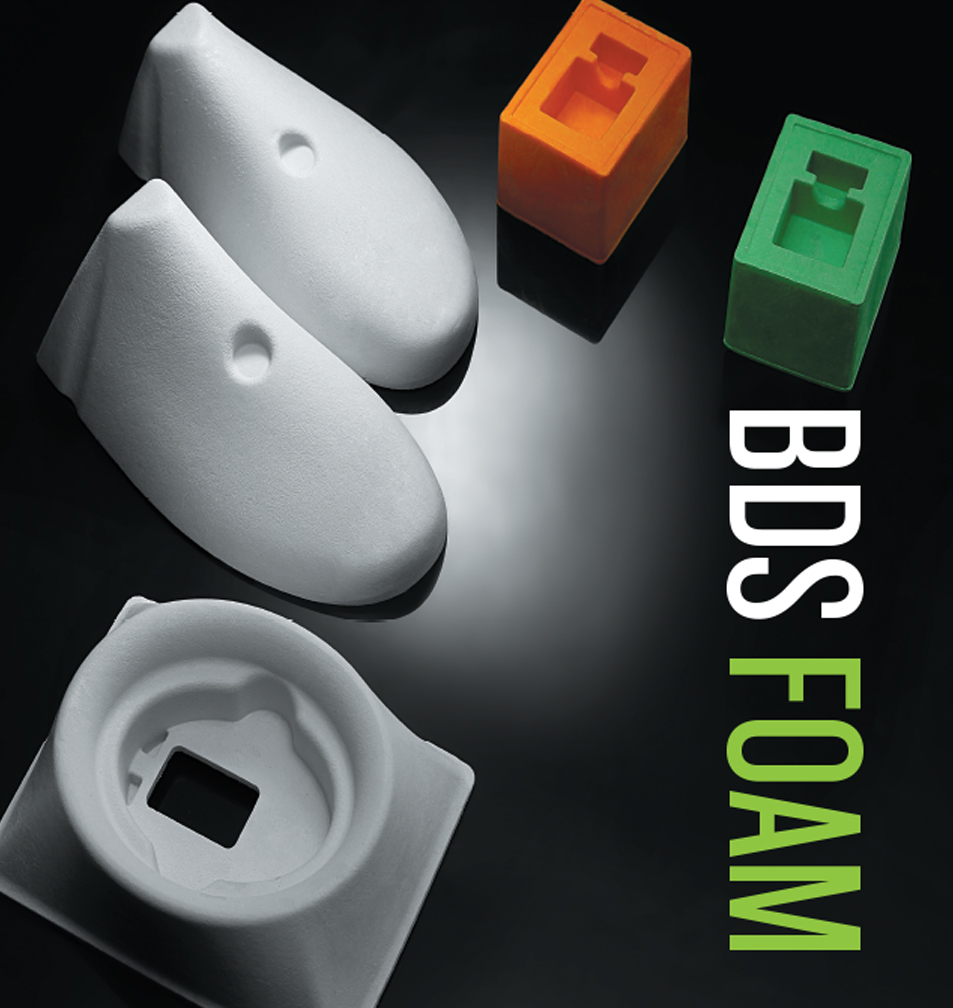

BDS FOAM is a non-hazardous and non-polluting packaging product. It is 100% biodegradable and recyclable, mainly composed of botanical starches and fibers from corn and potatoes, plus natural polymers.

The component ingredients are put through a room temperature fermenting process, and a high-heat forming process, which results in a highly effective shock-absorbent, and 3D moldable material.

There are no waste water emissions, or gasses in the manufacturing process. Additionally, this material meets the E.U.'s strict Essential Requirements for Packaging.

Our partner company is focused on the production of specialized materials and packaging - such as shrink wrap, foil bags, poly bags, PE bags, OPP bags, as well as a wide variety of stickers and decals.

The plastic and foil bags - can use a range of materials; PET, OPP, CPP, CPE, and so on.

PET shrink film, such as you'd see on a plastic bottle, comes in thicknesses from 0.03 mm to 0.06 mm, and can be color printed.

OPP and CPP can be produced/used separately or combined. OPP+CPP composite material is the most popular composite bag produced in China.

CPE allows for translucent and white frosted styles. The material is biodegradable, automatically breaking down after 5 years.

We have major production facilities for these packaging types and materials in both Shenzhen, China, and North Vietnam.

We currently produce packaging using these materials for many of the worlds top brands in electronics, toys, novelty items, alcohol and tobacco, pharmaceuticals, and more.